Reset Relap

When we receive your tools, we carefully clean and thoroughly sort them based on the level of edge wear and the presence of any chips. We have the capability to reset the PCD segment with exceptional precision, removing only the minimal amount necessary to restore and sharpen the edge effectively. This meticulous and controlled process allows us to perform multiple reset cycles on the same tool.

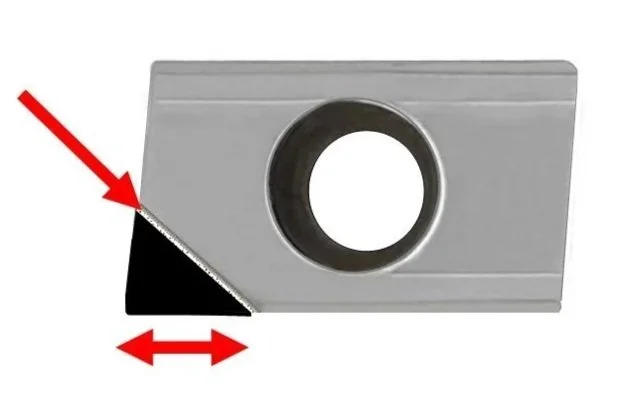

A shim is carefully placed behind the PCD segment, which allows us to precisely regrind the tool to new dimensions, effectively removing any chips, wear, or surface imperfections.

This procedure does reduce the PCD edge length slightly, which in turn directly affects the depth of cut (DOC) that can be achieved during the machining process.

Below are some examples of edges that are excellent candidates for this particular procedure.